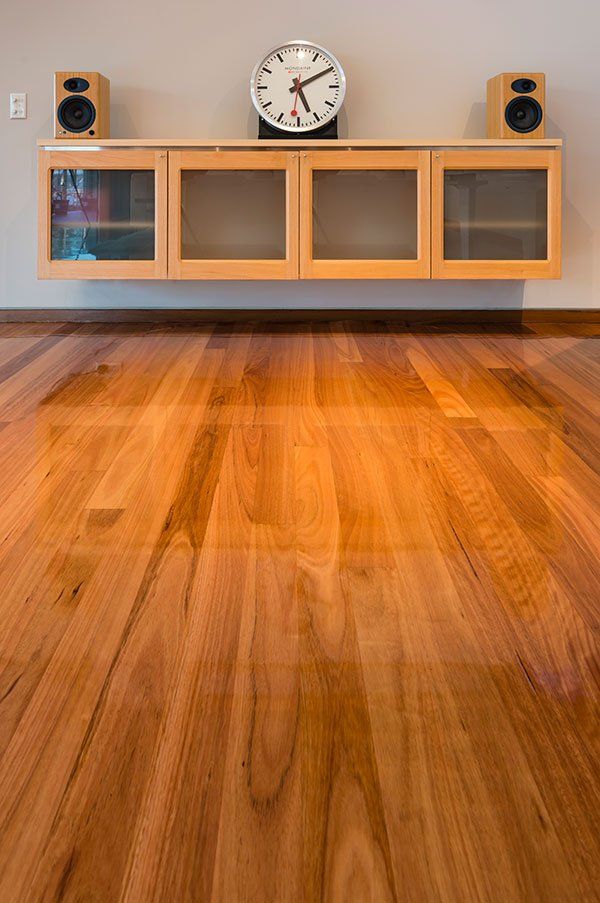

TIMBER FLOORING

Strip timber flooring is a good alternative to obtain a solid timber floor which can be installed in a variety of situations.

About Solid Timber Strip Flooring

Solid timber strip flooring is the ideal selection to produce a beautiful and long lasting floor. Correct installation is imperative to realizing the floor’s potential.

As timber is a natural product, and responds to its surrounding environment, it is important to ensure the product is acclimatized prior to installation.

It is a hygroscopic material that is, it changes its own moisture content to be in equilibrium with the atmosphere (EMC (Equilibrium Moisture Content). As this moisture is taken up or expelled, the physical dimensions of the material also changes. Most timber flooring products are kiln dried to a level of moisture content within a range of 8-14% as specified in the Australian Standard 2796.

Timber will either take up or shed moisture to be in equilibrium with the prevailing conditions. Moisture content (MC) refers to the percentage weight of water present in the timber compared to the weight of the timber with all the water removed (dry weight).

Where timber is installed in conditions where the prevailing conditions are moist, either through the local climatic conditions or specific site conditions, the timber absorbs moisture and increases the dimensions of the board. Conversely, where prevailing conditions are drier than that of the timber in its delivered state, the timber will shrink.

Timber is a beautiful natural flooring product so some shade variation will be seen in any floor which is unavoidable, but we consider this adds character to the floor.

Gluing

The glues used to adhere timber flooring must be specialist elastomeric glues. Glues that set hard, such as contact or general building adhesives, are not suitable and can lift off the substrate.

Nailing

Building regulations govern the size and number of nails used to fix strip flooring to joists. Boards over 85 mm wide MUST be surface nailed.

Only boards 85mm wide or less can be secret nailed. Overlay and panel floors should be nailed in accordance with the manufacturer’s instructions. We note that strip timber floors are different to floating floors as floating floors are not fixed to the substrate but are held down by skirting boards.

Types of Installation

Installation may take anywhere between 4 days and 14 days to complete, depending on the size of the flooring area. There are two key types of installation:

Direct Stick

Timber is nailed or stuck directly to an existing sub-floor.

On Battens

Battens are secured to the sub-floor and the timber is either secret nailed or top nailed.

On Underlay

Timber is installed on a masonite flooring underlay that has been secured to a suitable sub-floor.

As with any floor, preparation is the key to ensuring a high quality finish.

We have a proud history of providing an exceptional product and service to our customers and we offer a full supply and installation service to take the hassle out of your flooring experience.

DO YOU HAVE AN EXISTING CORK FLOOR AND WANT TO GIVE IT A NEW LEASE ON LIFE?

Read more about our Resanding and Resurfacing processes here.

Download our Catalogue Today

COPYRIGHT © 2022 CORK INTERIORS / ALL RIGHTS RESERVED.